DXP HP-Plus Pumping System

2. Adjustable V-shaped pump cradles provide for reliable centering while horizontal and vertical adjustments allows for easier alignment.

3. Optional API-610 seal flush systems and thrust chamber oil cooling systems, as required.

4. Thrust Chamber is bi-rotational, tilting pad design, rated for 18,000 ft-lbs continuous duty, with rear pull out feature for easy maintenance and standard API-682 seal chamber.

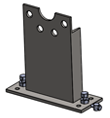

1. Adjustable discharge flange support helps protect the pump from static pipe loads and reduces piping fit problems during installation.

7a. Bolt-on removable motor pads allow the skid to accept the next larger motor frame without major skid modification.

5. Bolt-on skid extension allows skids to easily be extended to accommodate longer pump lengths due to future operating conditions.

6. Intake and discharge drip pans with drain plugs for spill containment capture potential piping and mechanical seal leakage.

7b. Motor mounting adjustment screws standard for ease of installation and alignment.

2. Adjustable V-shaped pump cradles provide for reliable centering while horizontal and vertical adjustments allows for easier alignment.

3. Optional API-610 seal flush systems and thrust chamber oil cooling systems, as required.

4. Thrust Chamber is bi-rotational, tilting pad design, rated for 18,000 ft-lbs continuous duty, with rear pull out feature for easy maintenance and standard API-682 seal chamber.

1. Adjustable discharge flange support helps protect the pump from static pipe loads and reduces piping fit problems during installation.

7a. Bolt-on removable motor pads allow the skid to accept the next larger motor frame without major skid modification.

5. Bolt-on skid extension allows skids to easily be extended to accommodate longer pump lengths due to future operating conditions.

6. Intake and discharge drip pans with drain plugs for spill containment capture potential piping and mechanical seal leakage.

7b. Motor mounting adjustment screws standard for ease of installation and alignment.

1. Adjustable discharge flange support helps protect the pump from static pipe loads and reduces piping fit problems during installation.

2. Adjustable V-shaped pump cradles provide for reliable centering while horizontal and vertical adjustments allows for easier alignment.

3. Optional API-610 seal flush systems and thrust chamber oil cooling systems, as required.

4. Thrust Chamber is bi-rotational, tilting pad design, rated for 18,000 ft-lbs continuous duty, with rear pull out feature for easy maintenance and standard API-682 seal chamber.

5. Bolt-on skid extension allows skids to easily be extended to accommodate longer pump lengths due to future operating conditions.

6. Intake and discharge drip pans with drain plugs for spill containment capture potential piping and mechanical seal leakage.

7a. Bolt-on removable motor pads allow the skid to accept the next larger motor frame without major skid modification.

7b. Motor mounting adjustment screws standard for ease of installation and alignment.